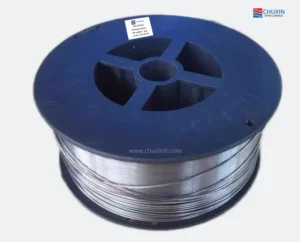

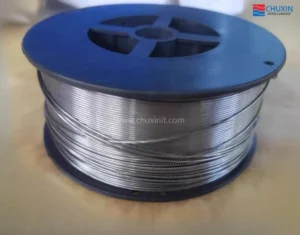

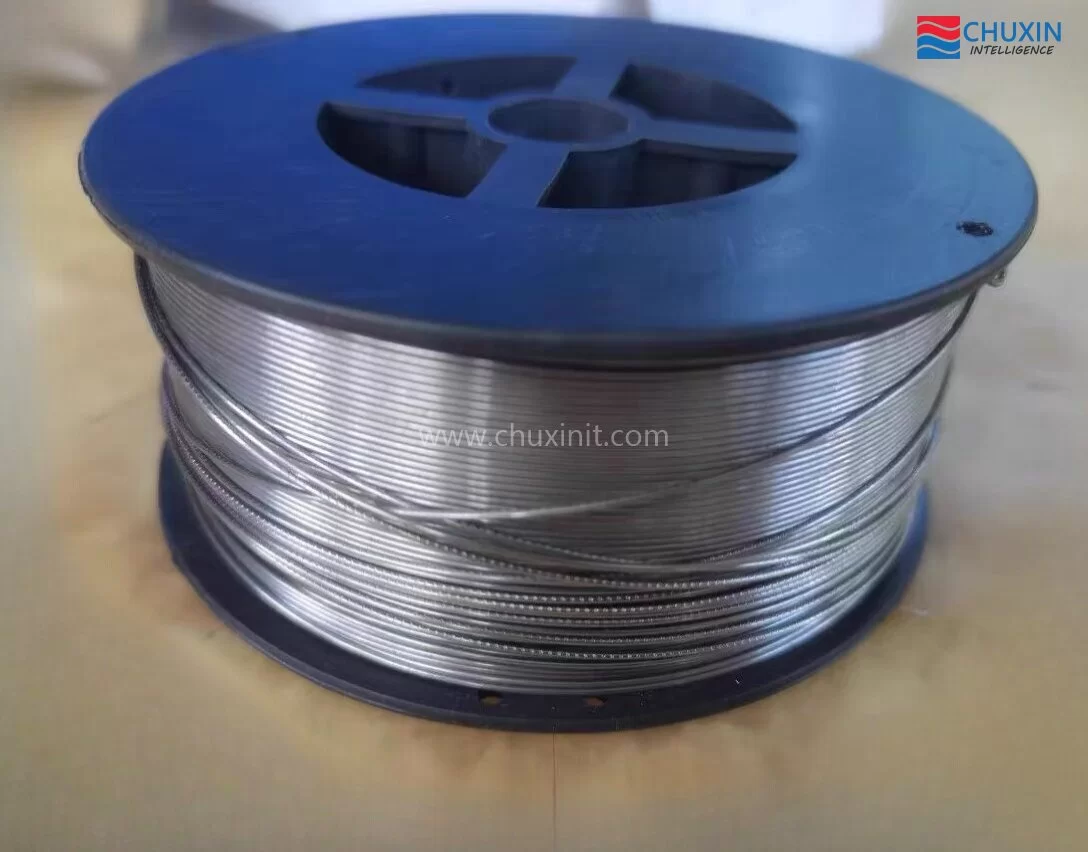

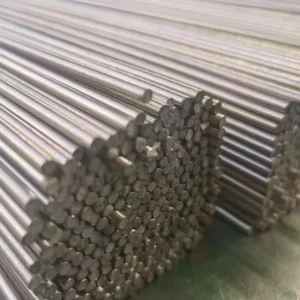

Stainless steel MIG welding wire

Contact with usStainless Steel MIG Welding Wire rod AWS A5.9 ER304,304L,ER308 ER308L ER308LSi ( 308 308L 308LSi ),ER309,ER309L,ER316,ER316L,ER317,ER317L

Diameter: 0.8mm,0.9mm,1.0mm,1.2mm,1.6mm

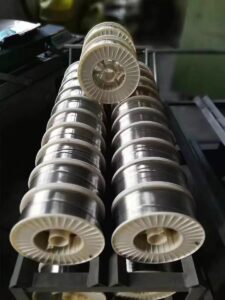

Weight: 1kg,5kg,15kg,customized weight

Spool’s diameter:D100mm, D200mm, D270mm, D300mm, K300mm

Precautions:

1.Clear rust, oil, water and other impurities on the weldments before welding.

2. It is recommended to use Ar+(1%-3%)O₂ as shielding gas in MIG welding, and use pure argon as shielding gas in TIG welding.

3. The user should develop an appropriate production welding specifications according to the circumstances.

Advantages:

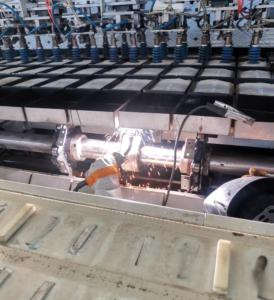

2.High productivity and low electricity consumption.

3.Easy to operate.

4.Very low hydrogen content in the weld and lower nitrogen content.

5.All position welding.

6.Excellent crack-resistance.

7.Little deformation after welding.

8.Wide applicability. Suitable for welding thin, medium and thick plates.

Customized support: OEM,ODM

Loading Port: Qingdao,Tianjin,Shanghai,Ningbo,Shenzhen of China

MOQ:1kg

Warranty: 1year

Payment: T/T,West Union,L/C

Port: Qingdao,Tianjin,Shanghai,Ningbo,Shenzhen of China

MOQ:1kg

Warranty: 1year

Payment: T/T,West Union,L/C

| Matters needing attention: |

| 1. Wire into the plant must be stored in dry conditions, can not open welding wire coil waterproof packaging.

2. Welding shall be removed before welding surface oil, rust, water and other impurities. |

Reviews

There are no reviews yet.